Complete control over scales, inventory, and waste – directly from the kitchen.

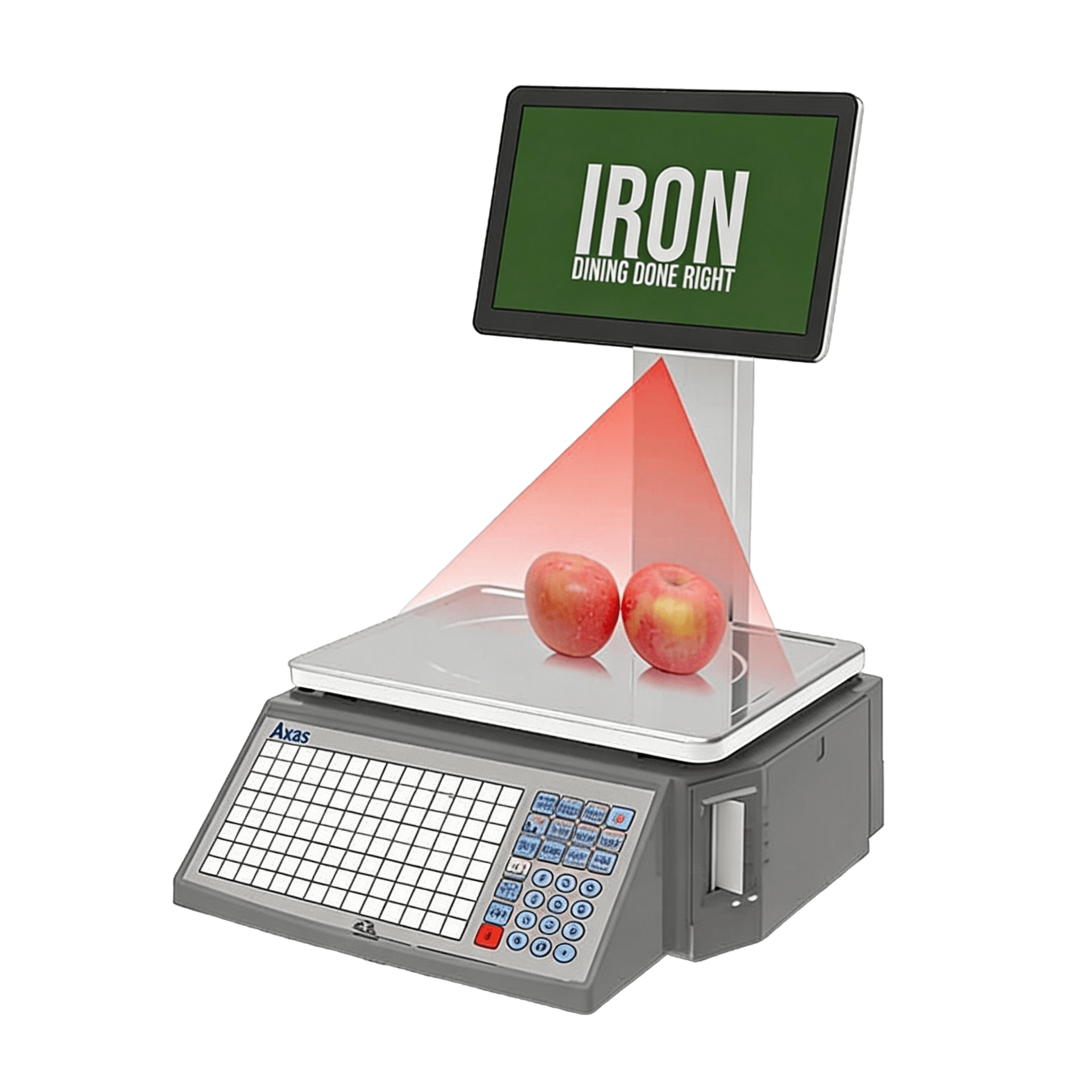

Iron Scale System is an integrated weighing system for precise management of scales in the kitchen and at the counter. The system connects directly to Iron POS to reduce errors, optimize inventory control, and provide full control over raw materials. Instead of manual counts and Excel sheets – you get full automation that tracks what goes in, what comes out, and what remains at any moment.

Common results:

-

10–15% reduction in waste

-

Significant savings in inventory counting time

-

Tight control over Food Cost

Why invest in a smart weighing system?

Common challenges:

-

Discrepancies between theoretical and actual usage: “Where did kilograms of raw materials go?”

-

Tiring manual counts: Hours of work and low accuracy.

-

Service shortages: Dishes running out during peak times.

-

Waste and spoilage: Ingredients not used on time.

-

Inaccurate Food Cost: Discrepancy between intended and actual cost.

The solution: Iron Scale System

-

Automated documented weighing: Every weigh-in is recorded for tracking.

-

Connection to POS: Sales automatically reduce inventory based on digital recipes.

-

Real-time dashboard: Inventory status, shortages, and alerts.

-

Smart waste reports: Theoretical vs. actual, anomaly detection.

-

Alerts: Minimum inventory, expiration dates, and abnormal patterns.

How does the system save money?

-

Reducing waste and spoilage

The system creates a digital recipe for each dish (accurate quantities for each ingredient). With every sale, the inventory is automatically reduced accordingly. At the end of the day/week, differences between theoretical and actual consumption are reviewed, identifying sources of waste (over-portioned dishes, improper storage, errors, or theft), and corrective actions are taken. This reduces waste by 10–15% in a measurable way. -

Control over Food Cost

Displays theoretical Food Cost (based on the recipe) vs. actual Food Cost (based on weighings and supplier prices). Identifies unprofitable dishes, updates recipes or prices, and increases profitability. -

Savings in counting hours

Real-time interfaces and weighings save up to 80% of the time spent on monthly inventory counts. Periodic verifications can still be performed, but daily work is significantly shortened.

How it works – Full integration with Iron POS

-

Mapping raw materials

Create a material database with SKU, units of measure, suppliers, and prices.

Set minimum inventory levels and alerts. -

Building digital recipes

Set ingredient quantities for each dish.

Calculate theoretical dish cost and target Food Cost. -

Weighing and preparation

Weighing at the kitchen/counter is automatically recorded in the system. -

Sale and inventory update

Sale at POS automatically reduces inventory based on the recipe, in real-time. -

Reports and control

Theoretical vs. actual, waste, Food Cost, current inventory, and movements.

Smart alerts and proactive management

-

Minimum inventory

Alerts when inventory drops below threshold – timely orders, no service shortages. -

Expiration and FIFO

Track batches and dates; proper use, fewer waste items. -

Anomalies

Identify excessive waste, unusual weighing times, “over-portioned” dishes.

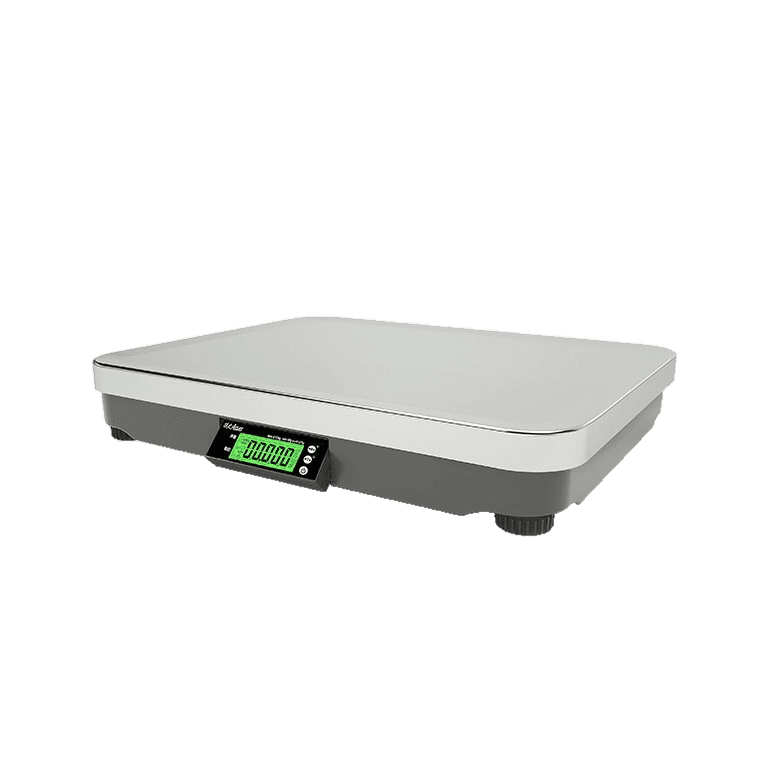

Technical specifications

-

Hardware – Professional scales

-

Counter/kitchen: Various capacities (3–30 kg), gram-level precision, stainless steel surface, clear display.

-

Floor models: High capacity for sacks/boxes, custom sizes.

-

Durability: Resistant to humid environments, temperature fluctuations, intensive use.

-

Connectivity: Wi-Fi / Bluetooth to connect to POS.

-

-

Software and Analytics

-

Materials and recipes database: Unlimited.

-

Real-time synchronization: Automatic inventory updates with sales.

-

Reports: Waste, Food Cost, inventory, movements, and trend analysis.

-

Security and permissions: Access control, activity log, and cloud backup.

-

Recommended implementation process

-

Consultation and needs assessment: Process mapping and weighing points.

-

Data mapping: Creating SKUs, suppliers, prices, and recipes.

-

Hardware installation: Scales and communication to kitchen/counter.

-

Integration with Iron POS: Flow checks and synchronization.

-

Training and launch: Kitchen and management team training; recipe updates.

-

Full operation: Dashboard, alerts, and control routines.

Typical implementation time: 4–6 weeks (depending on menu size and locations).

Business advantages in brief

-

Lower waste: 10–15% reduction in spoilage.

-

Accurate food costs: Full control over actual Food Cost.

-

Time savings: Up to 80% less time spent on inventory counting.

-

No manual errors: Less typing, more accuracy.

-

Preventing shortages: Inventory and expiration alerts.

-

Quick ROI: Direct savings on raw material costs and labor hours.

Who is it suitable for?

-

Full-service restaurants and QSRs: Tight control on high-volume production.

-

Catering and industrial kitchens: Large-scale weighings.

-

Cafes and bakeries: Recipe accuracy and quality consistency.

-

Chains and franchises: Unified inventory management across multiple locations.

Frequently Asked Questions

-

Do all scales need to be replaced? Not necessarily – if existing scales support communication, they can be integrated.

-

Does it work without internet? Yes, offline mode with automatic synchronization once the connection is restored.

-

Learning time? Kitchen: 20–30 minutes. Managers: 1–2 hours.

-

Adding dishes/recipes? Yes, flexible and immediate.

-

Does it support FIFO and batch tracking? Yes, full batch and expiration tracking.